- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

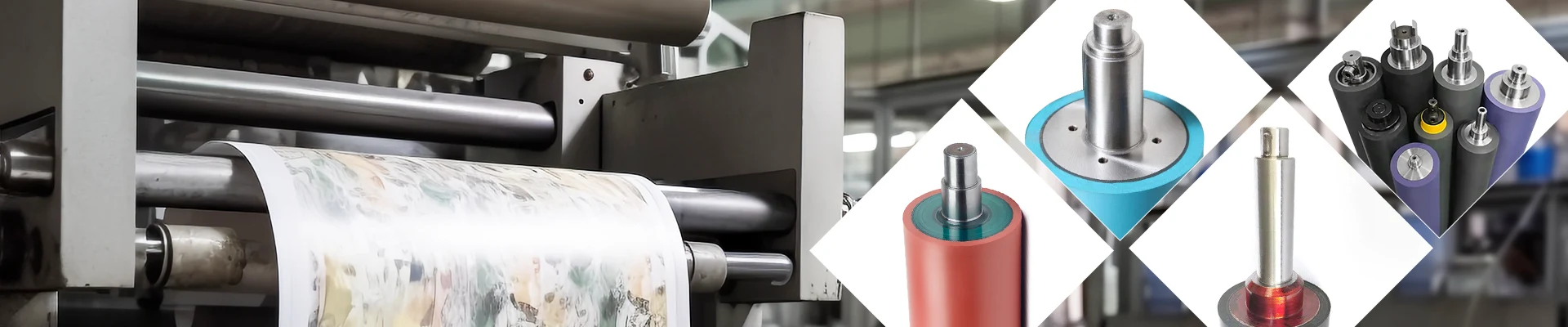

China Industrial Rubber Rollers Manufacturer, Supplier, Factory

As the professional manufacturer, we would like to provide you Haichang Industrial Rubber Rollers. Industrial rubber rollers find application in scenarios requiring significant contact and gripping friction. They are also employed in material processing tasks where a gentle touch is essential. These rollers typically come in cylindrical or spherical shapes, functioning as rotating devices, similar to spoke-less wheels, roller skates, or casters. In the realm of printing, hard rubber rollers play a crucial role in inking the type before paper impression. Rubber rollers are also highly suitable for peripheral decoration of cylindrical shapes and the roll-on decoration of large, flat, or curved surfaces. Covered rolls are extensively utilized in the graphic arts industry.

Industrial rubber rollers are essential components widely used in various industrial applications for their versatility, durability, and ability to perform under demanding conditions. These rollers are employed in a range of industries, providing crucial support in material processing, machinery, and manufacturing processes. Here's an introduction to industrial rubber rollers:

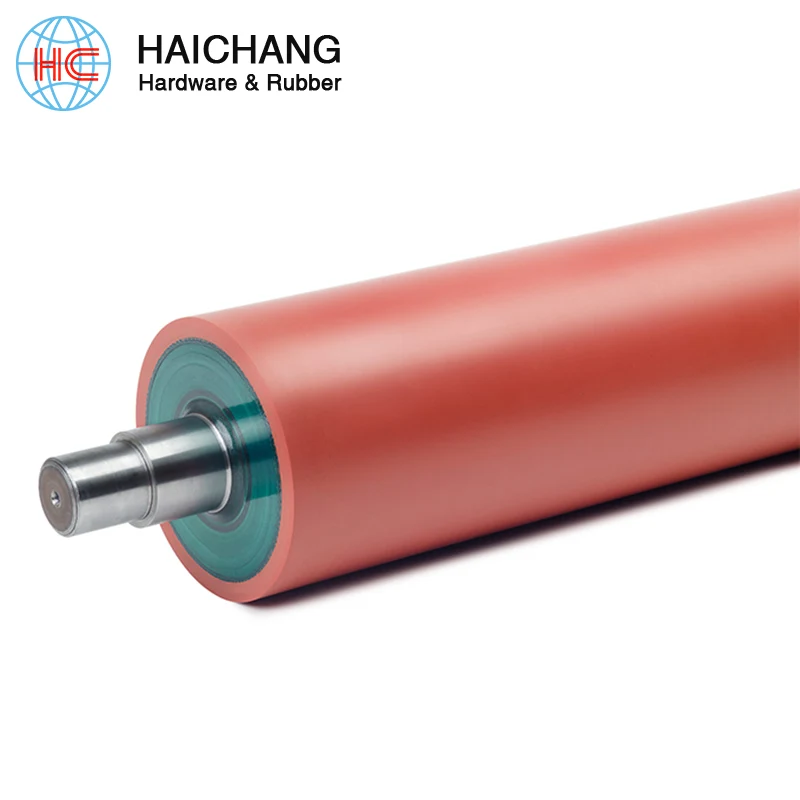

Material Composition:

Rubber Covering: The outer layer of industrial rubber rollers is typically made of rubber or a rubber compound. This rubber covering provides key characteristics such as elasticity, resistance to abrasion, and the ability to conform to irregular surfaces.

Core Material: The core or inner structure of the roller is often made of materials such as metals (e.g., steel or aluminum) or other rigid materials. The core provides strength, stability, and support to the roller.

Key Characteristics:

Abrasion Resistance: Industrial rubber rollers are designed to resist wear and abrasion, making them suitable for continuous and high-stress applications.

Elasticity: The rubber covering imparts elasticity to the rollers, allowing them to deform and recover during contact with surfaces. This elasticity is crucial for maintaining consistent pressure and contact.

Shock Absorption: Rubber rollers have inherent shock-absorbing properties, reducing vibrations and impacts. This feature is valuable in applications where a smooth and controlled material processing is essential.

Chemical Resistance: The rubber covering can be formulated to resist the effects of chemicals and oils, ensuring the rollers remain functional in diverse industrial environments.

Applications:

Material Processing: Rubber rollers are extensively used in material processing applications, including conveying, laminating, coating, and printing. They play a critical role in ensuring precise and consistent material handling.

Manufacturing Machinery: These rollers are employed in various manufacturing processes, such as those found in the metal, textile, paper, and plastic industries. They contribute to the movement, processing, and treatment of materials.

Conveying Systems: Industrial rubber rollers are utilized in conveyor systems to facilitate the smooth movement of materials within manufacturing facilities and warehouses.

Printing Industry: Rubber rollers are commonly used in printing presses for inking, dampening, and transferring ink to paper or other substrates.

Customization:

Industrial rubber rollers can be customized to meet specific requirements, including different hardness levels (durometers), sizes, and configurations. This allows for tailored solutions based on the unique needs of each application.

Maintenance and Service:

Regular maintenance and inspection are essential to ensure the optimal performance and longevity of industrial rubber rollers. This may involve cleaning, re-covering, or replacing rollers as needed.

- View as

Lamination Rubber Rollers

As the professional manufacturer, we would like to provide you Lamination Rubber Rollers. Since lamination requires heat in order to properly bond the two materials, laminating rolls must be fabricated from materials that are capable of high heat-resistance such as silicone, which is capable of withstanding temperatures of up to 500º F (260° C). Additional elastomeric materials capable of withstanding high temperatures include fluorocarbons, EPDM, neoprene, butyl rubber, nitrile butadiene (NBR) and chlorinated polyethylene.

Read MoreSend InquirySlitting Machine Rubber Roller

As the professional manufacturer, we would like to provide you Slitting Machine Rubber Roller. Excellent Abrasion Properties , Dynamically Balanced , Highly Durable & Light Weight.

Read MoreSend InquiryFood Machinery Conveying Rubber Roller

You can rest assured to buy Food Machinery Conveying Rubber Roller from our factory. Our Food Machine Rubber Roller Conveyor Accessories Roller boasts exceptional performance with excellent oil resistance and aging resistance. The fine and smooth surface of the rubber body ensures a robust and enduring bond with the core shaft. Enjoying superior stability, this roller exhibits resistance to high temperatures, acids, alkalis, salts, fluorocarbon compounds, and various corrosive additives found in lubricants and fuel oils. Additionally, the rubber roller maintains overall stability, with strict size control to prevent significant changes under diverse temperature and humidity conditions. Trust in this roller's reliability for your conveyor and food machine applications.

Read MoreSend InquiryCoating Machine Rubber Roller

You are welcomed to come to our factory to buy the latest selling, low price, and high-quality Coating Machine Rubber Roller. These rubber rollers are designed to deliver outstanding coating results. The specialized construction ensures a smooth and uniform application of coatings on various surfaces.

Read MoreSend InquirySander Rubber Roller

As the professional manufacturer, we would like to provide you Sander Rubber Roller. Haichang has served the wood finishing industry for many years, so we understand the important role of sander rollers.

Read MoreSend Inquiry